“Digital prototypes are the best way to design quickly. “Several pilot projects are already underway with top automotive, aerospace, and furniture companies,” adds Dinko Dimitrov, VRscans Product Manager. This complex data is read by the new VRscans plugin, creating a physically accurate material that can be rendered from any angle and in any lighting condition.

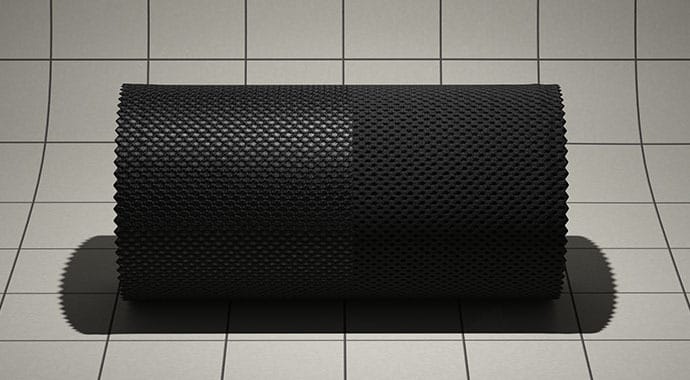

VRscans captures each material’s full appearance, including surface texture, reflectivity, dimensionality, and its unique response to light. VRscans combines precise optical hardware with proprietary software the result of several years of research and prototyping. “Now they can match the material sample in their hand with the one in their 3D model.” “We’ve dedicated the last 19 years to advancing rendering technology, so designers can trust what they see on their screen,” said Peter Mitev, CEO at Chaos Group. vrscan file ready to render in their proprietary V-Ray software. spent five times longer on VR scans than the participating experts in measuring foetal crown-rump length (CRL) and also spent around 11 minutes scanning. Companies can send in their material samples for 3D scanning and will receive a.

Computer graphics technology company Chaos Group unveils a new 3D scanning technology that is capable of capturing digital replicas of a physical material with sub-mm precision.Ĭhaos Group makes this technology available to design and manufacturing companies through their VRscans service.

0 kommentar(er)

0 kommentar(er)